M2001-EKO for optical measurement of dissolved oxygen

Optical sensor ESKO12

- Luminescent optical method for measuring the concentration of dissolved oxygen

- Accurate measurement without the need for regular calibration

- It does not consume oxygen during the measurement and therefore does not require flow around the sensor

- Adjustable bracket adapted for quick installation of the rod sensor in the correct position

- 10 m long cable at the hanging sensor.

- RS485 sensor communication interface under Modbus RTU protocol compatible with M4016 and M2001E units

- Internal temperature sensor for measuring water temperature

- Supply voltage in a wide range from 10 to 24V DC

M2001E display unit

- Display of dissolved oxygen value and water temperature

- 3 programmable relays for blower control and alarms

- 2 galvanically isolated active output signals 4-20 mA

- Recording of measured values and statistics (min, max, ...)

Application

Operational optical oximeter M2001-EKO is designed for continuous measurement of dissolved oxygen in many areas of water management:

- Wastewater treatment plants

- Technological processes in industrial production

- Monitoring the water quality of streams and rivers

- Fishing

Basic description

The set for optical measurement of dissolved oxygen consists of a separate ESKO12 sensor and an M2001E display unit. Both devices are interconnected by a cable terminated by a detachable connector, after which the ESKO12 sensor from the M2001E unit is powered and after which there is also a mutual digital communication between the devices via the RS485 bus under the Modbus RTU protocol.

ESKO12 sensors can also be connected directly to the control and recording unit type M4016.

As an optional accessory, a universal DE2 holder is usually included in the delivery of the rod sensor, which allows this sensor to be installed at an inclination important for correct measurement.

Principle of optical measurement of dissolved oxygen

Principle of optical measurement of dissolved oxygen

The ESKO12 sensor works on the principle of measuring the intensity of radiation on the luminescent layer of the measuring head of the sensor caused by a short light pulse of high energy generated by the electronics of the sensor. Oxygen atoms absorb the energy of the pulse, which would otherwise be emitted in the form of photons by the phosphor atoms, and therefore the concentration of dissolved oxygen in the measured solution is inversely proportional to the measured intensity of the luminescent radiation.

The sensor also regularly measures the intensity from the phosphor of the reflected light of low energy (it does not cause luminescence) and uses this measured value during the actual autocalibration of the sensor.

Unlike Clark-type electrochemical sensors, optical sensors do not require regular calibrations, do not need to change electrolyte or clean the chemically worn anode, and last but not least, do not require solution flow around the measuring head because they do not consume any oxygen atoms in the measurement.

Characteristics of the ESKO12 optical sensor

- Robust mechanical design of the ESKO12 rod sensor - stainless steel tube with a diameter of 40 mm and a length of 1750 mm (500 snímače 4000 mm long on request).

- ESKO12 dissolved oxygen sensor with DE2 holder The suspended version of the ESKO12-Z sensor is adapted for hanging the sensor on the supplied 10 m long cable. The cable is terminated with a 5-pin M12 connector with IP67 protection.

- The sensors are placed in the measured medium at an inclination (30 to 45 degrees) to prevent the accumulation of gases on the surface of the luminescent measuring head (the inclination prevents the formation of an air pocket at the phosphor).

- The luminescent method of measurement does not consume oxygen during the measurement and therefore the sensor does not require the flow of the measured medium around the measuring head.

- Unlike the commonly used Clark electrochemical sensors, the optical sensor does not need to change the electrolyte and there is no gradual decay of the anode due to ongoing chemical reactions.

- The sensor does not require calibration by the user (automatic autocalibration takes place during each measurement). It is recommended to verify the accuracy of the measured value only once a year with another reliable oximeter and to set a possible correction in the connected recording unit.

- After 2-3 years of operation, the phosphor in the replaceable measuring head may be depleted. By fitting a new measuring head, the correct function of the sensor is restored.

Characteristics of the M2001E display unit

Clear and understandable MENU together with a large number of adjustable parameters allow to optimize the measurement with regard to the needs of connected devices (dosing pumps, single or two-speed blowers, frequency converters). Parameters include, for example, damping of fast changes of the measured quantity or limits and hysteresis of own and external relays. The M2001E calibration unit can control 3 own and up to 12 external relays in the DV2 or DV3 switching units.

Clear and understandable MENU together with a large number of adjustable parameters allow to optimize the measurement with regard to the needs of connected devices (dosing pumps, single or two-speed blowers, frequency converters). Parameters include, for example, damping of fast changes of the measured quantity or limits and hysteresis of own and external relays. The M2001E calibration unit can control 3 own and up to 12 external relays in the DV2 or DV3 switching units.

Automatic cleaning of the electrode (sensor) can be performed with the help of the programmable time relay "Rinses". The last measured value remains fixed at the current output during the rinsing time and during the calibration or recalibration.

One of the relays itself can be set as the output of the PI controller. The controller constants are set from the MOST program via RS232.

The plug-in module of the second 4-20 mA current output can be used for temperature transfer or as another output of the measured quantity.

A KR1 stainless steel cover can be ordered for the M2001E outdoors.

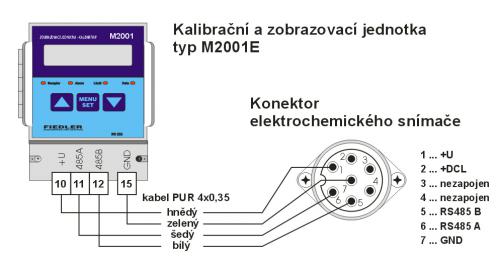

M2001E terminal connection:

Connecting the connection cable for the M2001E:

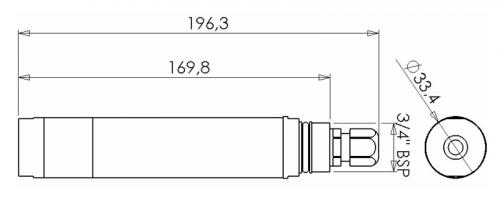

Dimensions of the ESKO12-Z pendant sensor:

| Parametr | Hodnota |

| Měřící metoda | optické měření vybuzené luminiscence |

| Měřící rozsah | 0,00 až 20,00 mg/l |

| Přesnost | +/-0,1mg/l |

| Rychlost odezvy | dosažení 90% hodnoty za < 60 sec |

| Četnost měření | min 1 měření/sec |

| Pracovní teplotní rozsah | -10 až +60 °C |

| Maximální pracovní tlak | 5 bar |

| Rozměry ESKO12 (průměr x délka) | 40 x 1750 mm |

| Materiál snímače | nerezová ocel, Tecaform |

| Průměr luminoforu měřící hlavice | 10 mm |

| Hmotnost tyčového snímače ESKO12 | 2200 g |

| Hmotnost závěsného snímače ESKO12-Z | 1150 g |

| Délka kabelu snímače ESKO12-Z | 10 m, konektor M12 |

| Napájecí napětí | 12 až 24 V DC |

| Interface | RS485, protokol Modbus RTU |

| Teplotní kompenzace | interní NTC |

| Krytí | IP68 |

| Parametr | Hodnota |

| Displej | alfanumerický 2 x 16 znaků, 9 mm, řízený kontrast |

| Klávesnice | 3 hmatníky, mechanická odezva stisku |

| Hodiny reálného času | typ odchylka do 160 sec/rok |

| Datová paměť | 240 000 hodnot |

| Napájecí napětí | 12 až 24 VDC |

| Proudová spotřeba | max 90 mA / 24 V DC |

| Analogový výstup | 4-20 mA, aktivní, galvanicky oddělený |

| Rozlišení analogového výstupu | 16 bitů |

| Relé Limit, Alarm, Oplachy | spínací kontakt 230 V/4A |

| Připojení PC-notebooku k jednotce | rozhraní RS232 |

| Program určený pro parametrizaci jednotky | MOST |

| Pracovní teplotní rozsah | -20 až +50°C |

| Rozměry jednotky (v x š x h) | 220 x 160 x 115 mm |

| Hmotnost | 960 g |

| Krytí | IP54 |

| Propojovací kabel ke snímači | stíněný PUR kabel 3 m |

| Max. délka propojovacího kabelu | 500 m po prodloužení |

Main menu

- Solutions

- Tap water treatment

- Dispatching accessible via the Internet

- Remote water meter reading

- Monitoring of water leak

- Measurement of qualitative water parameters

- Measurement in Water Supply Network

- Pressures and flows regulation

- Controlling of water pumps and water reservoirs

- Controlling technology of waste purification plants

- Flow processing into charts

- Waste water treatment

- Monitoring of running and technology of WWTP

- Control technology of WWTP

- Measurement of waste water flow

- Dissolved oxygen measurement and aeration blowers control

- Measurement of chemical parameters of water

- Local control of pumping stations

- Remote control of pumping stations

- Root zone waste water treatment plants

- Dispatching accessible via the Internet

- Processing of measured flow data

- Water level monitoring

- Flood warning system

- Environmental monitoring

- Water level and flow monitoring in small water-courses

- Temperature measurement in bore holes and water basins

- Monitoring of soil humidity and temperatures

- Measurement of rain-fall quantity and intensity

- Level measurement in boreholes and remote data collecting

- Measurement of water temperature and conductivity in boreholes

- Measurement of well yield – pumping tests

- Water-level regulation in boreholes

- Capacity and intensity of drainage water

- Thermal balance in ecological constructions

- Meteorological stations

- Relative humidity and air temperature, rainfall, global radiating, atmospheric pressure, speed and direction of wind

- Satellite transfer while the GSM signal is unavailable

- Meteorological stations for agriculture and research institutes

- Extension of meteorological stations about special sensors

- Different type of tower constructions

- Data transfers into the Internet

- Special kinds of graphs for visualization

- Irrigation control systems

- Data collecting and processing

- Data hosting on the server

- Software MOST

- Parameterization of stations via the Internet

- Transferring of measured data into a current dispatcher programme

- Visualization and processing of data

- Data exports from the server into the PC

- Overview reports working-out and printing

- An automatic emails sending

- Types of SIM cards

- Operating costs of the telemetric station

- Industrial applications

- Tap water treatment

- Products

- Monitoring and control units for water supply

- Small telemetric stations and data loggers

- Smart Metering - remote meter readings

- Water level meters

- Hydrostatic level meters

- Radar level meters

- Ultrasonic level meters

- Level gauges for wells, boreholes and reservoirs

- Level float switches

- Equipment for pumping tests of boreholes and wells

- Local Warning Systems

- Flow meters for open channels

- Water quality sensors

- Meteorological stations and measuring sensors

- Accessories for control units and data loggers

- Boxes and cabinets for telemetry and control units

- Gel accumulators, batteries and backup sources

- AC power supplies and battery chargers

- Photovoltaic solar panels

- Antennas and extension cables

- Sensor cables, connectors and connecting expanders

- Communication signal converters and communication cables

- Mechanical mounting elements

- Industrial and residential water meters

- Server software and services

- References

- Support & Download

- About us

- Monitoring

- Datahosting

- OPTIMA Control unit

Documentation

Download

Application

no related solutions